Introduction

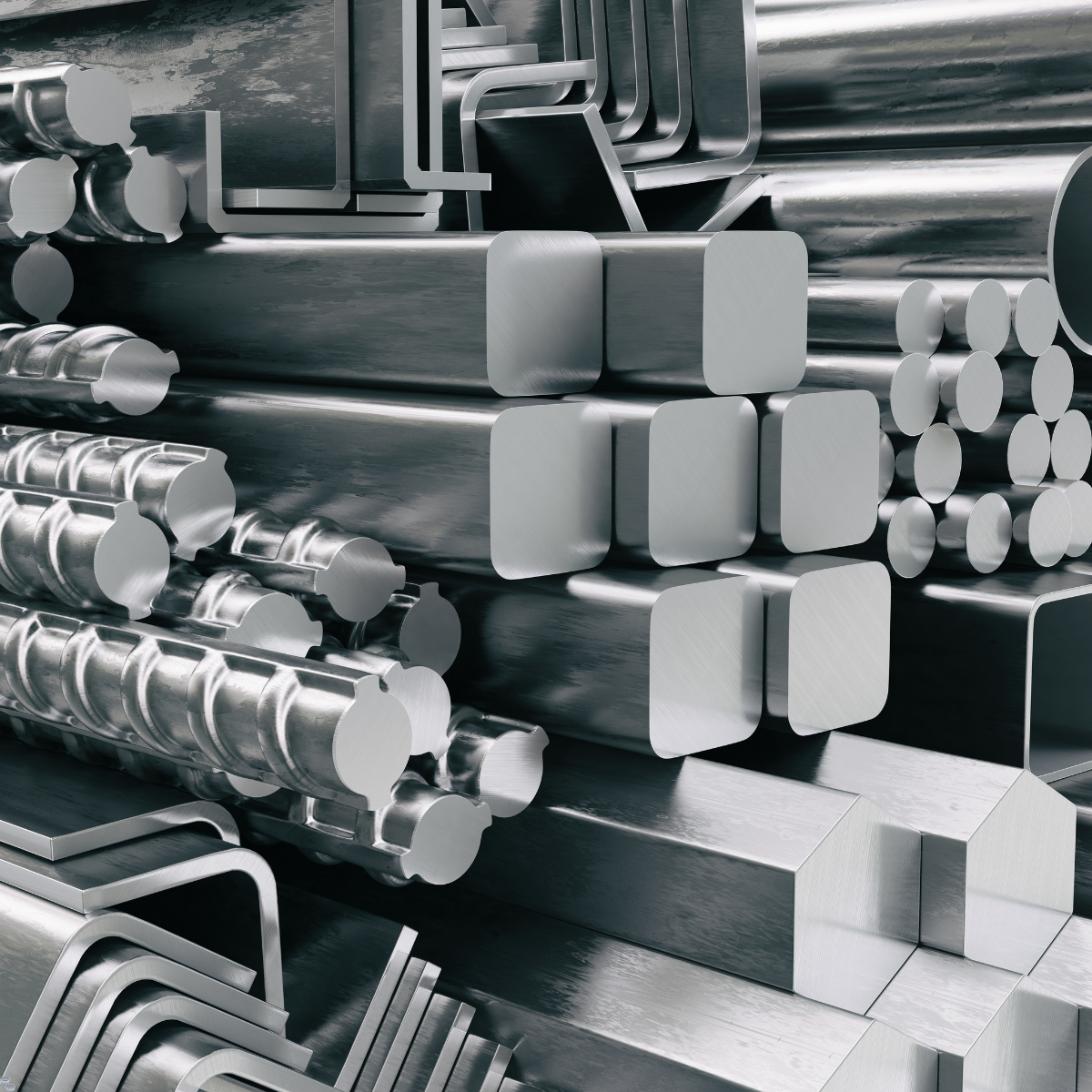

17-4 PH Stainless Steel, also known as UNS S17400 or Type 630, is a precipitation-hardening martensitic stainless steel. Renowned for its combination of high strength, corrosion resistance, and excellent mechanical properties, 17-4 PH is widely used across various industries, including aerospace, medical, chemical, and marine applications. Its versatility stems from its ability to achieve a wide range of strength and toughness through heat treatment.

Chemical Composition

The composition of 17-4 PH Stainless Steel includes:

- Iron (Fe): Balance

- Chromium (Cr): 15.5-17.5%

- Nickel (Ni): 3-5%

- Copper (Cu): 3-5%

- Manganese (Mn): ≤ 1%

- Silicon (Si): ≤ 1%

- Carbon (C): ≤ 0.07%

- Phosphorus (P): ≤ 0.04%

- Sulfur (S): ≤ 0.03%

The addition of chromium ensures corrosion resistance, while copper and nickel enhance its precipitation-hardening capabilities.

Key Properties

- High Strength and Hardness: 17-4 PH can achieve tensile strengths exceeding 1,100 MPa and high hardness levels, making it suitable for load-bearing applications.

- Corrosion Resistance: The alloy offers excellent corrosion resistance in a variety of environments, including mildly acidic and marine conditions.

- Heat Treatability: By applying different heat treatment conditions (H900, H1025, H1075, etc.), the mechanical properties can be tailored to meet specific application requirements.

- Good Machinability: In its solution-treated condition, 17-4 PH is relatively easy to machine compared to other high-strength stainless steels.

- Excellent Wear Resistance: The alloy’s hardness and toughness contribute to its wear resistance, especially in dynamic or abrasive environments.

Applications

- Aerospace: Commonly used for aircraft fittings, fasteners, and structural components requiring high strength-to-weight ratios and corrosion resistance.

- Medical: Utilized in surgical instruments, orthopedic implants, and dental tools due to its biocompatibility and mechanical properties.

- Marine: Its resistance to corrosion in saltwater environments makes it ideal for marine shafts, propeller shafts, and other underwater hardware.

- Chemical Processing: Suitable for valve components, pumps, and heat exchangers due to its ability to withstand corrosive chemicals.

- Industrial Tooling: Used for molds, dies, and other high-stress tooling where strength and wear resistance are critical.

Heat Treatment

The defining characteristic of 17-4 PH Stainless Steel is its precipitation-hardening ability, which involves the following steps:

- Solution Treatment: Heating to 1,025–1,065°C and air cooling or quenching to dissolve precipitates.

- Aging (Precipitation Hardening): Reheating to temperatures between 480–750°C to precipitate copper-rich phases, enhancing strength and hardness.

The aging process results in different conditions (H900, H1025, etc.), each offering a unique balance of strength, toughness, and ductility.

Challenges and Limitations

- Limited Ductility in High-Strength Conditions: As strength increases through aging, ductility may decrease, which could limit its use in applications requiring high flexibility.

- Cost: The alloy’s advanced properties and processing requirements can make it more expensive than other stainless steels.

- Sensitivity to Chlorides: In environments with high chloride concentrations, 17-4 PH may be susceptible to stress corrosion cracking.

Conclusion

17-4 PH Stainless Steel is a versatile and high-performing material that excels in applications demanding a balance of strength, corrosion resistance, and wear resistance. Its adaptability through heat treatment makes it a go-to choice for engineers and manufacturers across industries. With continued innovation in processing techniques, the scope of applications for 17-4 PH Stainless Steel is likely to expand further, cementing its status as a critical material in modern engineering.

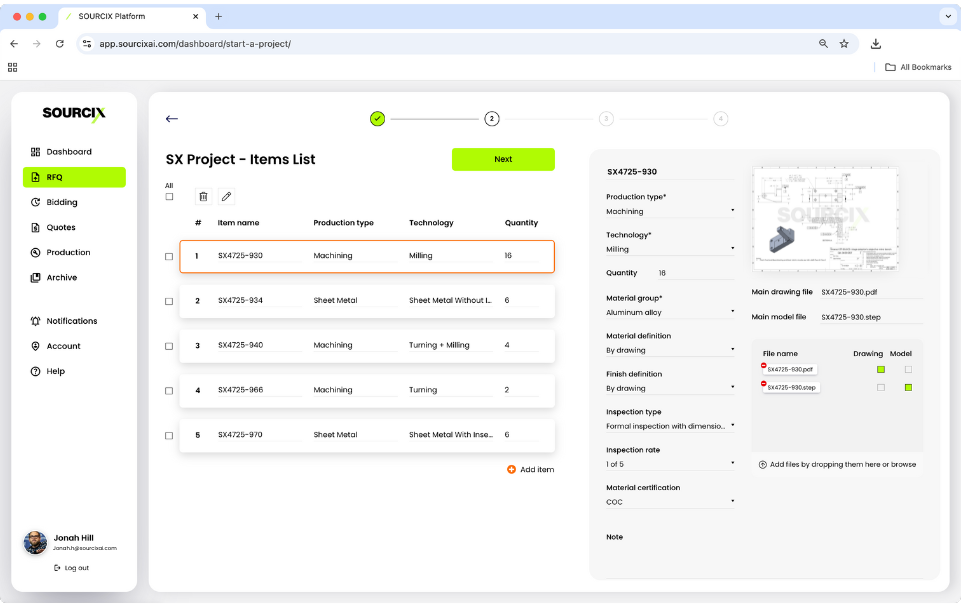

Upload multiple files all at once.

Upload multiple files all at once.